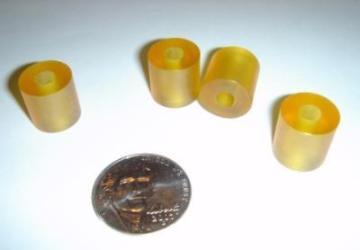

Natural PEI (trade name Ultem)spacers for a food application.

Natural PEI (trade name Ultem)spacers for a food application.

Material needed to be FDA compliant and was used in a

machine that was subjected to large amounts of thermal cycling. Ultem was recommended because it has excellent resistance to these conditions. The parts were made by screw machining with a tolerance of +/-.002 inch

transition chute for a dry food application. The large flange in the middle is used to mount the chute in place as product flows through it. You can see a quarter in the lower right of the picture for size

comparison. It is about 18 inches tall. It was made by heat forming the plastic

to shape in a special fixture and then welding a seam down the side. Then the flange was fabricated and welded in place. We are experts in plastic welding.

an ECM Machine. We are experts in

components for these machines which are in essence reverse electroplating

processes. These were produced by

CNC turning and then nickel plating

the entire body. Then an extremely

thick (.010) platinum plating was added at the tip to prevent corrosion

CNC machining to an industry standard tolerance of +/-.005 inch. Bryton has an excellent reputation for material recomendation of plastics and metals alike.

In this close up view of an industrial sink made from PVC, you can see how the components are welded to create a finished product. This unit has multiple compartments, a sloped bottom to facilitate draining and ribs welded in to raise parts off the bottom of the sink. PVC is very chemically resistant.

In this close up view of an industrial sink made from PVC, you can see how the components are welded to create a finished product. This unit has multiple compartments, a sloped bottom to facilitate draining and ribs welded in to raise parts off the bottom of the sink. PVC is very chemically resistant.

semiconductor processing machine. Due to its chemical make up, clear PVC has a slight blue tint. It has two sliding access doors and was made by hand fabricating to fit the customer's equipment. The pieces were fit together and solvent welded in place. Solvent welding is often called gluing, but it is actually creating a weld and like a weld, the joint is stronger than the surrounding material. If done properly, it will not break-the surrounding material will give out first.

Bryton producted these 316 stainless steel covers by laser cutting the 1/4 inch blanks and finish machining with ciountersunk holes and radiused edges. They are about 7 inches in diameter.

Bryton producted these 316 stainless steel covers by laser cutting the 1/4 inch blanks and finish machining with ciountersunk holes and radiused edges. They are about 7 inches in diameter.